- FREE SHIPPING ON $40 AND ABOVE

Majority of the products manufactured and being vended in the market these days contain the same components found in fabrics. This is the prime reason why fabrics are very important. And if there is one industry that can be considered as heavy users of both woven and non-woven fabrics, that is the medical industry. According to the research of the European Commission Enterprise and Industry conducted in 2010, the sector of technical textile has experienced a significant increase of 20% in the volume of textile consumption worldwide in the previous years and it identified the medical industry as one of the important users.

In the article written by Amy Willbanks, the vice president of Textile Fabric Consultants, Inc., she mentioned that fabrics are considered as life saving devices in medical industry. They are essential in producing numerous medical applications. The clothes of hospital workers as well as the patients are all made of fabrics. Aside from hospital workers and patients apparel, the medical equipments, medical dressings and supplies, hospital furniture, as well as medical prostheses contains fibers from plants, animals, minerals, and even synthetic or man-made fibers. For instance, an artificial kidney with 2-inches diameter and is used in dialysis contains 7,000 hollow fibers; more than 50% of the Jarvik-7 artificial heart is also composed of fabrics; and the artificial arteries designed to help prevent clotting and rejection and is being used by thousands of people in the United States are made of polyester. Medical prostheses are not the only ones that contain the same component found in fabrics. The casts for broken bones, surgical masks, bandages, hospital mattresses, blankets, curtains, wound dressings, gloves, face masks, surgical drapes and wraps are also made from two or more fabrics.

Fabrics can be classified in different ways and one of them is according to their manufacturing techniques. Basically, there are two classifications of fabrics in terms of manufacturing process and these are the woven and the nonwoven. Those fabrics that undergo the traditional manufacturing technique wherein fibers are interlaced at right angles are considered as woven fabrics while fabrics that are develop through modern manufacturing technique wherein small fibers are put together in a form of a sheet or web then bonded using mechanical, chemical, heat or solvent treatment are classified as nonwoven fabrics.

In health care industry, nonwoven fabrics are often used for production of medical products and equipments. The rising concerns over contagious diseases like AIDS, hepatitis, and resurgent tuberculosis as well as the additional protection standards required in hospitals and healthcare facilities brought a significant increase in the demands for nonwoven fabrics in medical industry. Nonwoven fabrics, according to research, are often used in manufacturing medical products today because they found to have better properties than woven fabrics especially terms of bacteria barrier, sterility, filtering, absorbency, liquid repellency, resilience, stretch, softness, flame retardancy, washability, and cushioning. Moreover, nonwoven fabrics are less expensive than their woven counterparts.

|

Major Uses of Nonwoven Fabrics in |

|

|

End-Use |

Product Samples |

|

Wound Care |

bandages, surgical dressings, burn dressings, |

|

Medical Prostheses |

artificial heart valve, artificial vascular graft, |

|

Hospital Textiles |

bed sheet, curtains, towels, drapes, wraps, |

|

Personal Protective Equipment |

medical scrubs, surgical gown, face masks, gloves, |

|

Personal Hygiene Supplies |

baby diapers, |

|

Medical Equipments |

hospital mattresses, surgical sutures, ambulatory |

|

Hospital Furniture |

consultation couches, cushions of waiting area benches and |

In an article

featured on Indian Textile Journal, it was predicted that the global

demand for nonwoven fabric on 2012 will reach to 8 million metric

tons. The largest single share of nonwoven fabrics in medical

industry will remain on personal hygiene supplies.

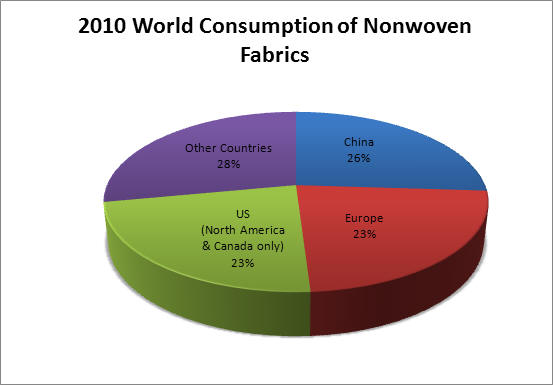

Meanwhile, in a separate report published on the website of IHS regarding the world consumption of nonwoven fabrics, it revealed that China (from its 26% share of the global nonwoven fabrics consumption in 2010) is still expected to have the largest volume increase in nonwoven consumption because of its population growth, urbanization, increased buying power/growing middle class, and product innovation. An additional 15% average annual growth rates is predicted until 2015. Europe will have 5% average annual increase while US (North America and Canada) will have 3.3%.

Data Source for Graph:

http://chemical.ihs.com/CEH/Public/Reports/540.9000/

Content Sources:

http://ec.europa.eu/enterprise/sectors/textiles/research-innovation/technical-textiles/

http://www.inda.org/about/nonwovens.html

http://www.textilefabric.com/site/main/articles.php?id=26

http://www.technicaltextile.net/medical-textiles/

http://www.indiantextilejournal.com/articles/FAdetails.asp?id=2041

http://chemical.ihs.com/CEH/Public/Reports/540.9000/